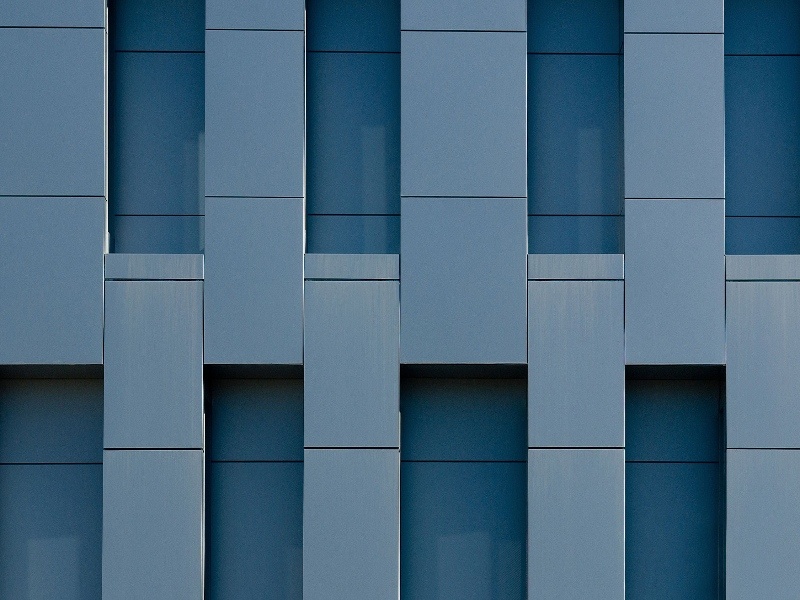

ALUMINIUM PANEL CLADDING SYSTEM

ALUMINIUM PANEL CLADDING SYSTEM

Aluminum panel cladding is a lightweight, durable facade system made from aluminum sheets that are either solid or composite (sandwiching a core material, often polyethylene or mineral-filled). Known for its corrosion resistance and low maintenance, aluminum cladding is widely used for exterior building facades, providing weather protection and aesthetic appeal.

ADVANTAGES

- Lightweight

- Durability

- Fire Resistance

- Aesthetic Versatility

- Thermal Insulation

- Easy Maintenance

- Sound Insulation

- Cost-Effective

- Eco-Friendly Options

- Quick Installation

TECHNICAL INFORMATION

| SPECIFICATION | DESCRIPTION |

|---|---|

| Material | Aluminum (composite aluminum panels) |

| Dimensions | Standard panel sizes (1220x2440 mm, 1500x3050 mm, etc.) |

| Weight | 3.5–5.5 kg/m² (for aluminum composite panels) |

| Thickness | 2–10 mm (aluminum panels) |

| Fire Resistance | Fire-resistant core available (A2 grade) |

| Wind Load Resistance | High (subject to system design and fixing method) |

| Installation Method | Dry mechanical fixing (clips, brackets, or cassettes) |

| Sustainability | High (recyclable material) |

| Maintenance | Low (periodic cleaning) |

| Impact Resistance | High (depends on core material and thickness) |

| Lifespan | 40–50 years (depending on conditions) |

Experts in Delivering Tailored Engineering Solutions

and Comprehensive After-Sales Support Services.

OTHER FACADE CLADDING SYSTEM pRODUCTS