PERFORATED SHEET CLADDING

PERFORATED SHEET CLADDING

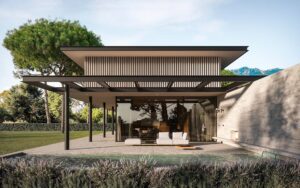

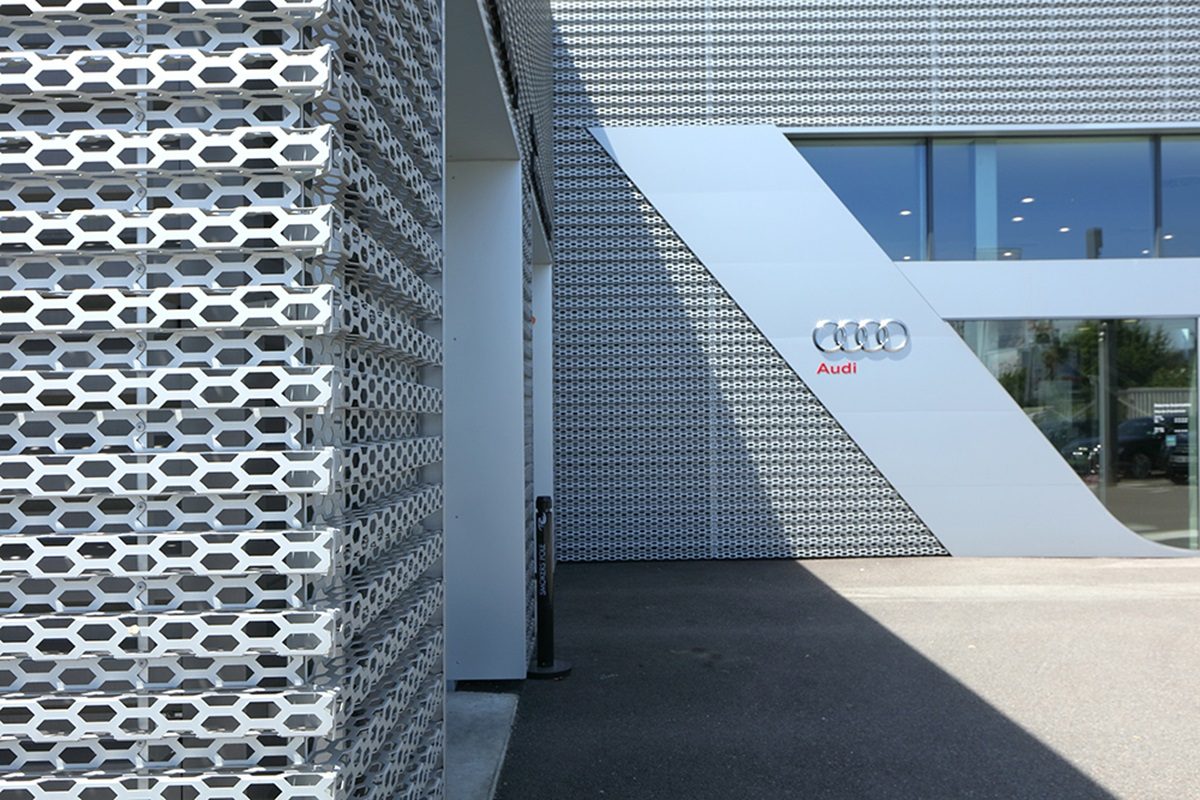

The perforated sheet cladding system utilizes metal sheets that have been punched with a pattern of holes to create a visually interesting facade. These sheets can be made from materials such as aluminum, stainless steel, or mild steel and are designed to be installed over a structural frame. The perforated sheets provide a unique combination of aesthetic appeal, functionality, and performance.

ADVANTAGES

- Aesthetic Flexibility

- Ventilation

- Light Diffusion

- Solar Shading

- Durability

- Low Maintenance

- Sustainability

- Fire Resistance

- Acoustic Properties

- Cost-Effective

TECHNICAL INFORMATION

| SPECIFICATION | DESCRIPTION |

|---|---|

| Material | Metal (aluminum, stainless steel, copper) |

| Dimensions | Custom sizes (mesh thickness typically 1–5 mm) |

| Weight | 3–12 kg/m² (depending on material and thickness) |

| Thickness | 2–10 mm (varies by application) |

| Fire Resistance | Non-combustible (Class A1 for metal) |

| Water Absorption | 0% (impermeable material) |

| Color Options | Available in natural metal finishes or powder-coated in a variety of colors |

| Maintenance | Low (requires occasional cleaning, resistant to corrosion if properly treated) |

| Impact Resistance | Medium to high (varies by material and mesh size) |

| Thermal Insulation | Low (can be combined with backing insulation layers) |

| Sustainability | High (recyclable materials, long lifespan) |

Experts in Delivering Tailored Engineering Solutions

and Comprehensive After-Sales Support Services.

OTHER FACADE CLADDING SYSTEM pRODUCTS